“Unleashing the Power of Embellishment” a recent webinar sponsored by Duplo and hosted by Printing Impressions, In-plant Impressions, and NAPCO Research, explored how enhancements such as spot UV, foil, and tactile coatings are helping print service providers unlock new markets, impress buyers, and most importantly, boost their bottom lines.

“Print is changing, moving away from the low-margin commodity printing of the past and becoming more of a value-added product — something people want to hold in their hands,” said Bob Neubauer, editor-in-chief and content director of In-plant Impressions as he opened the event on April 29, 2025. “Smart print providers are looking at embellishment features like spot UV coatings to enhance their work and increase its value.”

Printing and packaging expert and NAPCO Research analyst Cory Francer shared data that supports the growing appetite for embellished print. In one study of communication buyers, 75% reported they prefer to work with printers that offer services beyond basic ink on substrate. Another study found that 55% of brand owners and marketers specifically seek out providers that offer special effects such as foil stamping, spot gloss, or raised coatings, As Francer pointed out, that figure is likely even higher today.

Rejecting the Race to the Bottom

For Joan Escover, president of Santa Clara, California-based JP Graphics, embellishment was never about keeping up. It was about standing out. “I figured I was never going to win the race to the bottom for a 10-cent piece of paper,” she told the webinar audience. “So, I began to figure out how I could differentiate myself.”

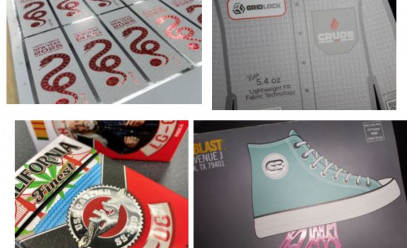

Escover’s journey started with the Xerox 1000i, which offered digital gold and silver printing. Today, Escover owns multiple embellishment systems, including equipment from Duplo, a PRINTING United Alliance member. By layering these technologies together, the team at JP Graphics, a PRINTING United Alliance and Women in Print Alliance member, built production capabilities that distinguished the business. Escover exclaimed,” It’s kind of an amazing way to really separate yourself from the pack.”

At Slate Group, a full-service PSP based in Lubbock, Texas, Trey Laverty took a similar leap — but with a twist. “We created this creative brand where our customers come to us saying, ‘What’s next?’” said Laverty, the company’s direct of sales development. “We’re not selling on price. We’re selling on experiences.” Slate Group added its first Duplo DuSense DDC-810 raised spot UV coater in 2017 and quickly discovered demand far outpaced expectations. Laverty recalls, “Once our reps saw it in action, they got excited. We started experimenting, and the machine never shut off.”

Laverty said the company has since added a second DDC-810 is preparing to install a Duplo DuSense DDC-8000 spot UV coater, which will allow the PSP to apply foil and spot UV in one pass and support variable data for embellishment, which will power high-value personalization campaigns for Slate Group’s customers. “That’s going to be a game changer for us in higher ed,” Laverty said. “Personalization is huge.”

Although adding new technology nearly always requires adjustment to a PSP’s operations and workflows, both Laverty and Escover emphasized that integrating embellishment into their existing workflows was relatively smooth. In fact, the process had an invigorating effect on the Slate Group team. “Our operators are cross-trained,” Laverty explained. “They run the digital presses, then jump on the Duplo. Once they understand it, it’s like, ‘OK, what can I do now?’”

Escover had a similar experience. “We started experimenting with different targets, different microns, different substrates. As we figured it out, that learning curve became part of the fun.”

Both print leaders also stressed the importance of getting hands-on with customers early in the design process. Laverty encourages his team to collaborate with clients from concept to execution. “Let’s create the piece you want, then figure out the right embellishment to bring it to life,” he said. “And if we have a crazy idea we can’t explain? We just print a one-off. Since it’s digital, we can test.”

Escover, too, uses samples and tactile demonstrations as a sales tool — but noted she often had to work harder to spark that initial interest in customers. “I felt a little alone out there at first,” she said. “Nobody even knew what embellishment was.”

Driving Demand for Embellishment, Maximizing Its ROI

Print buyers might not walk in the door asking for foil or raised UV but that doesn’t mean they aren’t open to the creative possibilities of embellishment. “Sometimes, people don’t know what they don’t know,” Laverty said. “So, you just have to show them.” Slate Group frequently prints two versions of a customer’s job: the standard version and an embellished alternate. “We hand them both and say, “What do you think of this?’ The smile on their face says it all.”

Escover uses a similar approach, even if the first sample is more of a passion project than a guaranteed sale. “I spent a lot of time not only doing my own marketing pieces, but also first articles just to show people what could be done,” she said. “And once somebody saw it, they were willing to pay for it.”

Both printers emphasized the power of using in-house marketing to showcase embellishments. Laverty’s team created a record-player-themed piece featuring dimensional UV, which customers immediately wanted to emulate. Escovar’s Lunar New Year bookmark campaign, originally a promotional giveaway, turned into an Etsy product and a lead-generation tool for higher education outreach.

These efforts, they say, drive long-term brand differentiation — even if the immediate financial gain is modest. “It’s not so much the profit margins for me,” Escover admitted. “It’s more. How can I put this? It’s more [about] the glory. I want my customers to win awards. Their award is my award.”

Still, the economic and operational benefits of in-house embellishment are real. Lavery noted that once Slate Group stopped outsourcing, they saved time, improved turnaround, and captured more profit. “We’re in an Amazon world,” he told the webinar audience. “Everyone wants things in two days. We don’t have the luxury of shipping things out and waiting. That’s why we brought everything in house.”

Both Escover and Laverty also agreed the learning curve is worth the effort, particularly because embellishment opens doors to new markets. “We’ve used it in everything from HR cards with soft-touch coating to cattle book for agriculture clients,” Laverty said. “It starts a conversation. Even if someone comes in for a basic postcard, they see our embellished samples and think, ‘You can do that? You can probably handle my job, too.’”

Escover shred that over time, embellishment has helped her pivot into more resilient sectors such as medical, pharmaceutical, and specialty packaging — sometimes for personal projects such as custom wine labels. “Now people find me because they want it,” she said.

For PSPs thinking about adding embellishment capabilities, both speakers had the same advice: Don’t wait! Escover said, “If you buy it, the work will come.” Laverty echoed those sentiments, saying, “Just go for it. Be creative in how you sell it, how you make it, how you partner with your customers. And then? Embellish, and go change the world.”

JP Graphics, a full-service printing company, is certified woman-owned and a small business by the state of California and is a Bay Area Green Company. Located at 3310 Woodward Ave, Santa Clara, CA 95054, our 33,000 sq. ft. facility houses a state of the art prepress department, numerous offset and digital presses, a complete bindery, including lamination, and diecutting. Additional services include fulfilment, large format, and mailing. We deliver all over the Bay Area and ship all over the world.